Device for transporting the rock mass in the quarry

For transportation of rocks in the granite quarries used a number of inventions:

- Skip hoist which comprises a drive station with rope drum, traction rope and the end rails. The disadvantage - the inability to use it on the track at an angle less than 100°C, which is not provided Samokatnaya motion skip, significant expenditure of time for unloading a skip in the curves of the track and the last significant metal content

- Vertical skip hoist which comprises a drive station equipped with rope drum, and skip hoisting rope. Disadvantage - limit its use only lifting cargo that under the granite quarries uslazhnyaet transport system and increases the cost transoprtirovki rock.

In order to achieve continuity of the transport sector and reduce the time required to unload vessels, a group of developers which included a gineralny and technical director of the company, has been solved this problem.

The problem was solved by the fact that in the device for transporting the rock mass in the quarry, the lift was made in view of the cage.

Wagon tippler and pusher are connected in series with a pulling rope tug and wagons to interact with the car in the place of loading and unloading the cage with her, and the wagon tipper is in the final paragraph where proihodit unloading wagons.

THE TECHNICAL RESULT: by introducing to the unit for transportation of rocks in a quarry of new elements is achieved increase in its load capacity decrease of metal and thus, increase productivity haulage.

TECHNICAL SPECIFICATIONS:

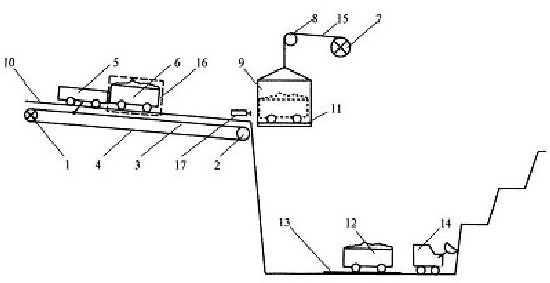

Fig. 2 - Device for transportation of rocks in a guarry (scheme)

1. Drive

2. End station

3. Working branch

4. Blank branch

5. Tug

6. 12. Wagon

7. The vertical lift with a drive unit

8. Vertical lift with diverting pulley

9. Crate

10. 11. 13. The rail track

14. Quarry

15. Hoisting ropes

16. Tipper wagon

17. Pusher

Application design, stand with the car instead skip to reduce the amount of congestion of the rock mass and thus increases the productivity of haulage.

Introduction into design of the apparatus and the pusher track in vertical lift cage permits faster exchange carriages and thereby increase the installation efficiency, generally, a continuous process transoprtirovki.