Construction project of a new mine in terms of designing a cargo, conveyor, human inclined shafts

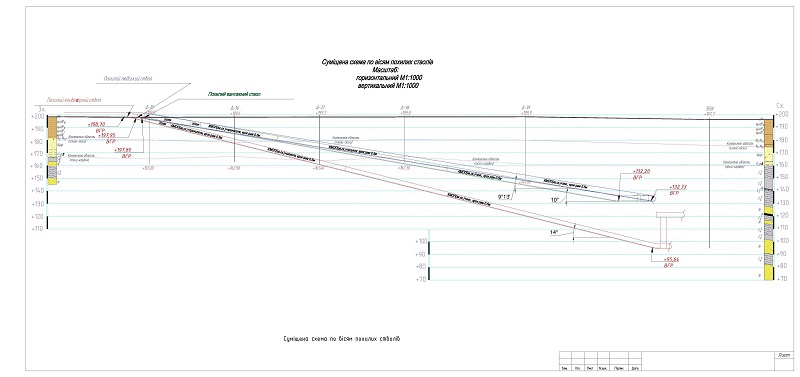

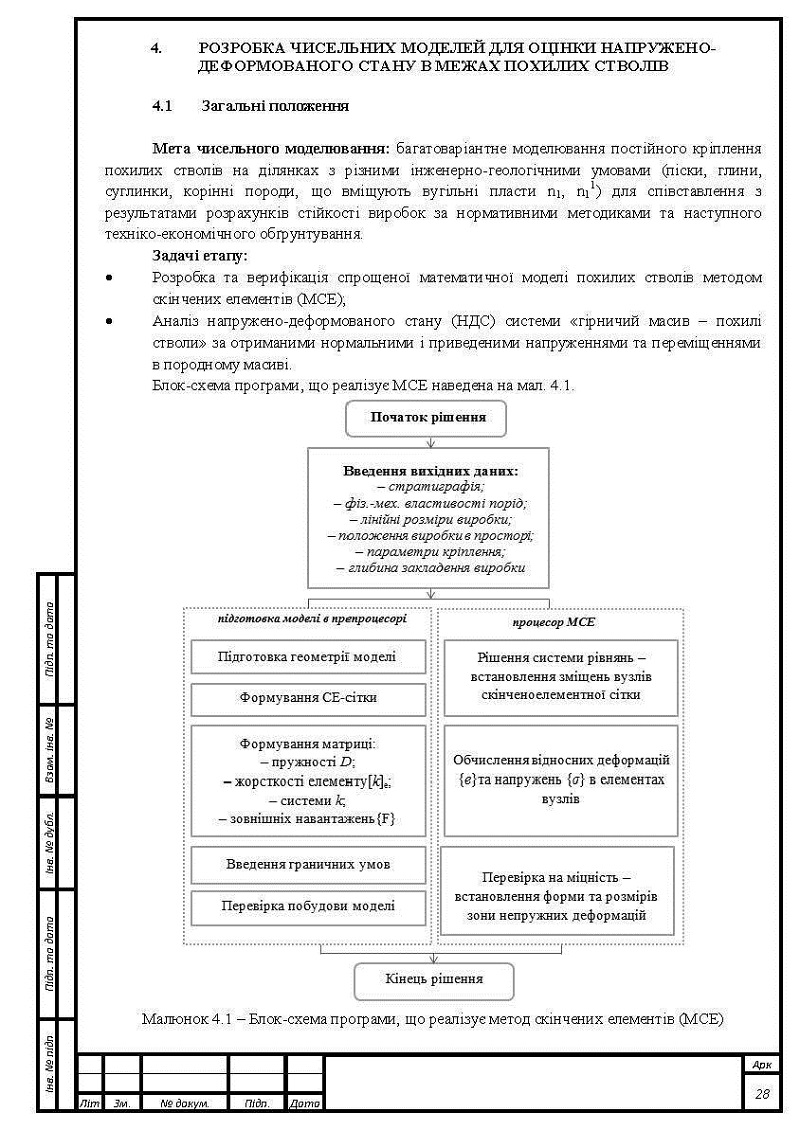

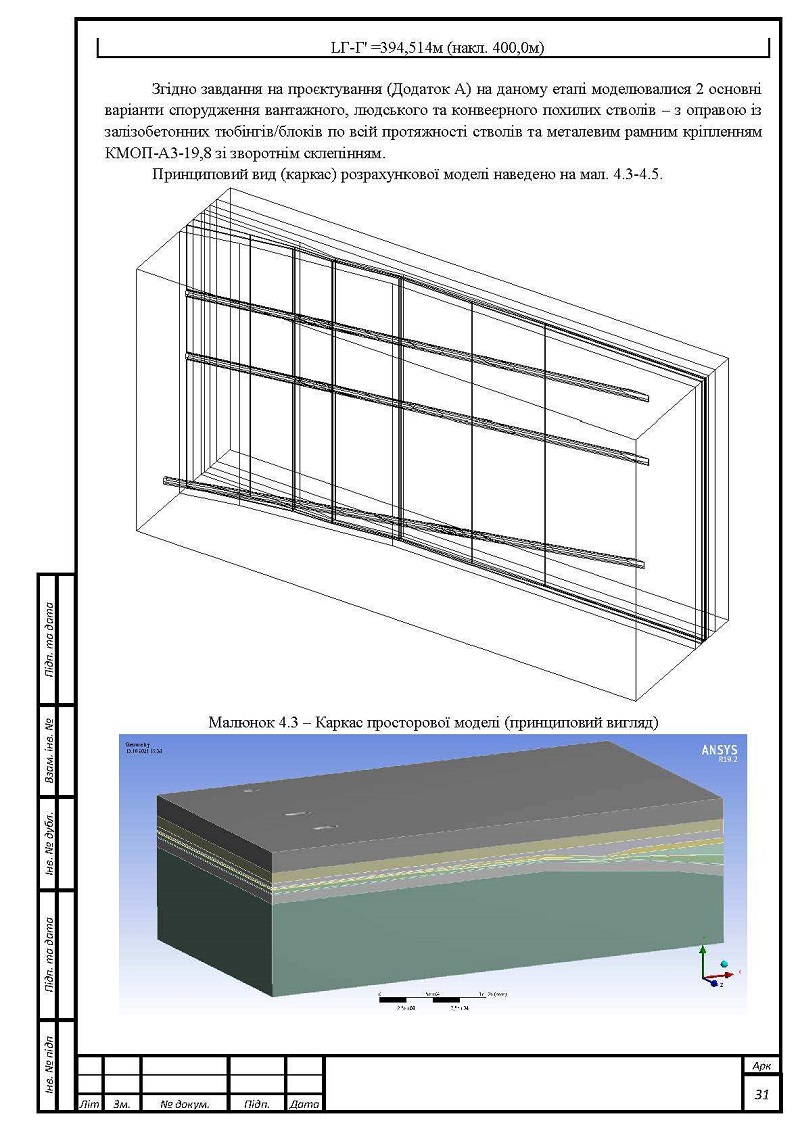

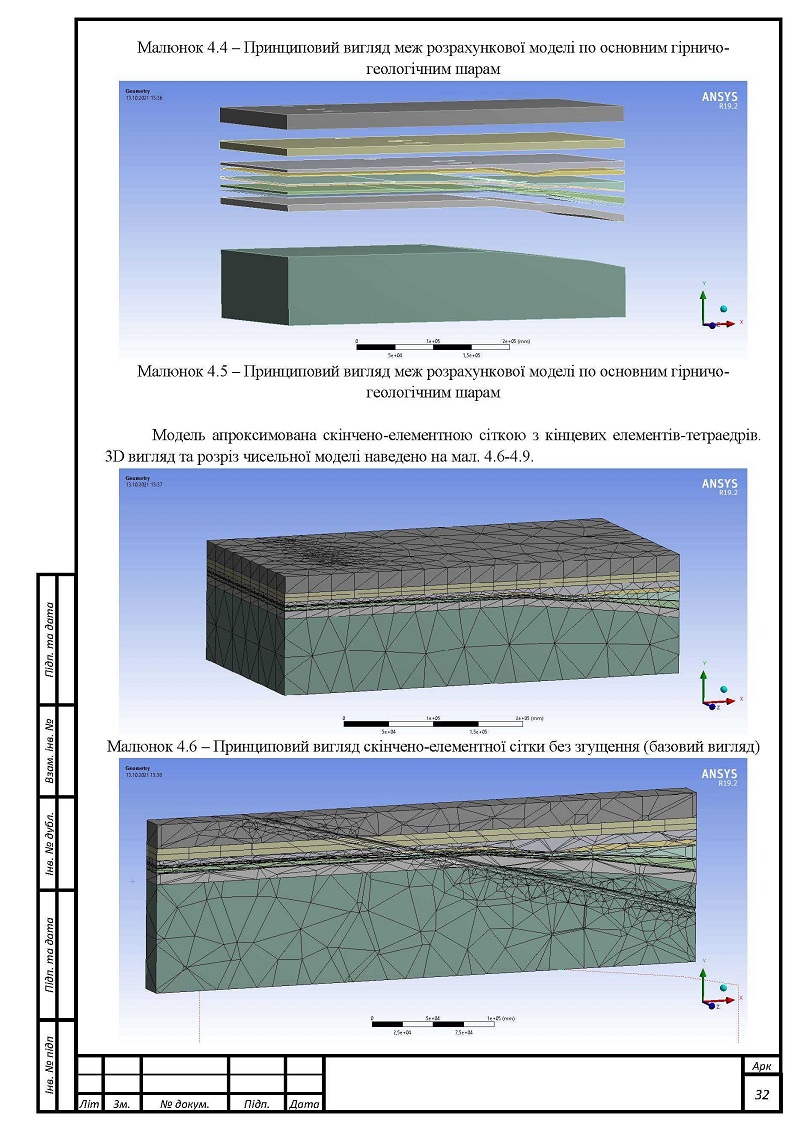

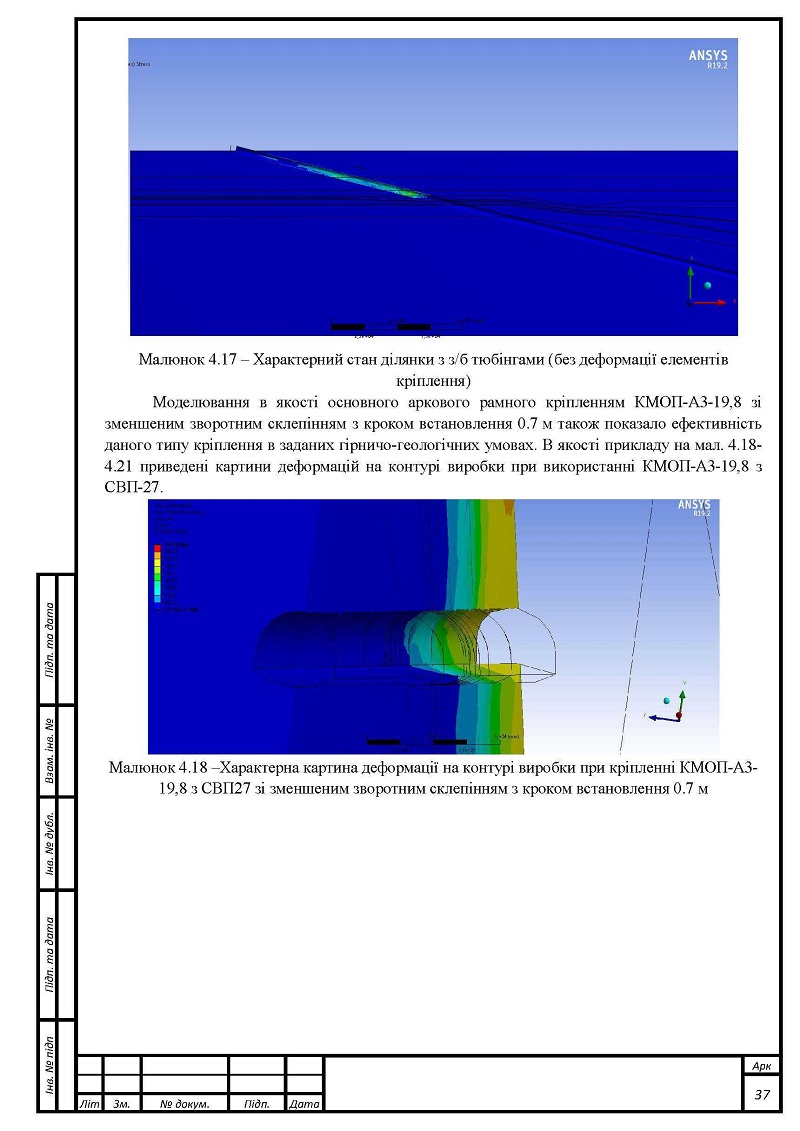

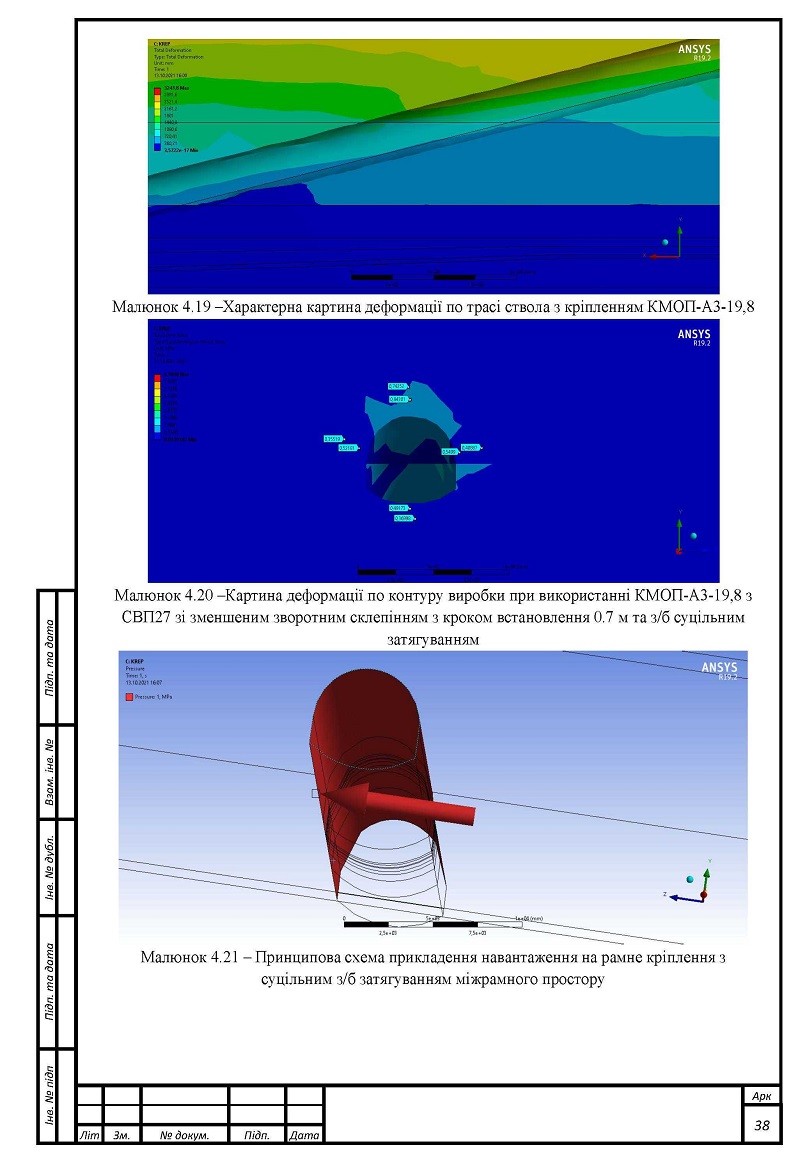

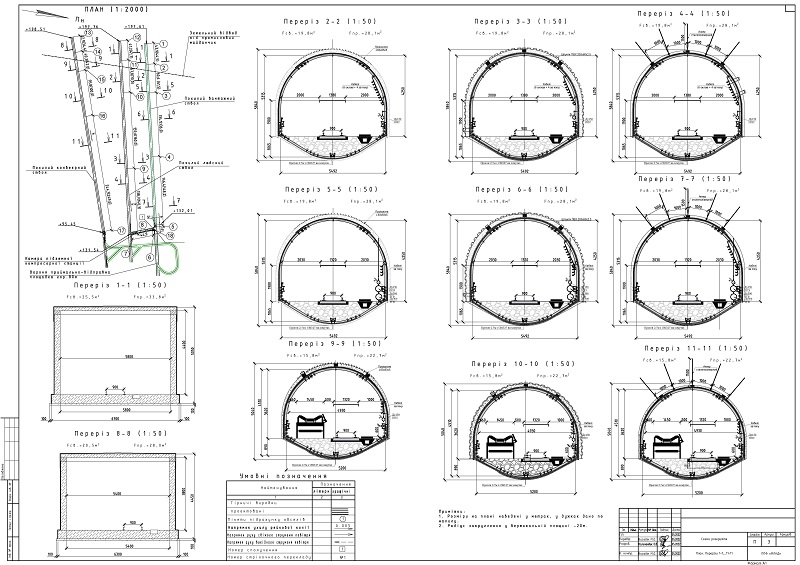

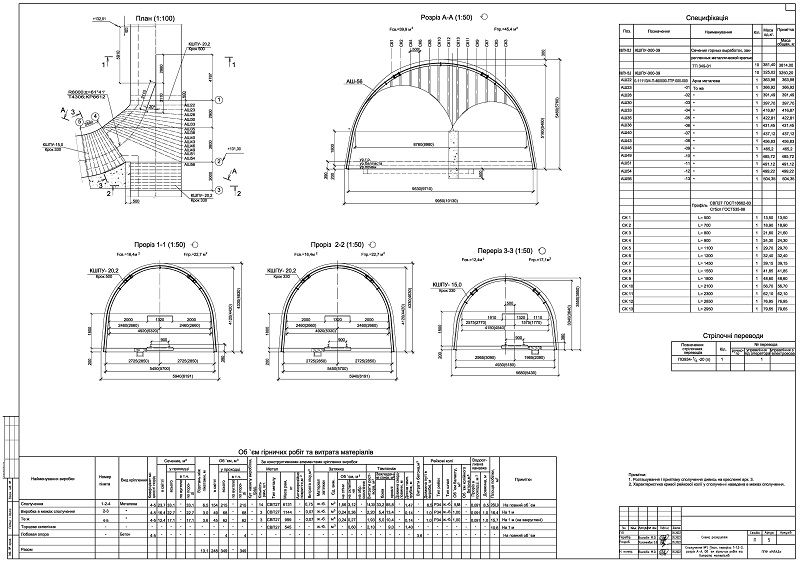

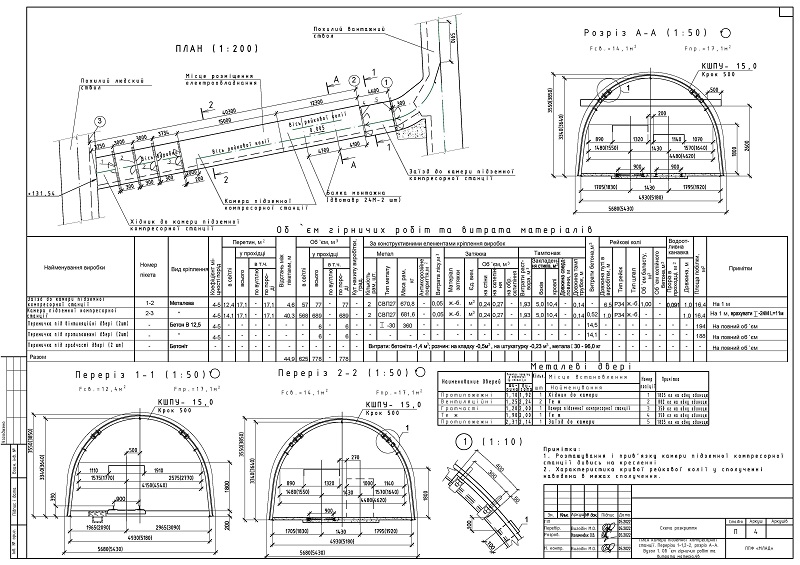

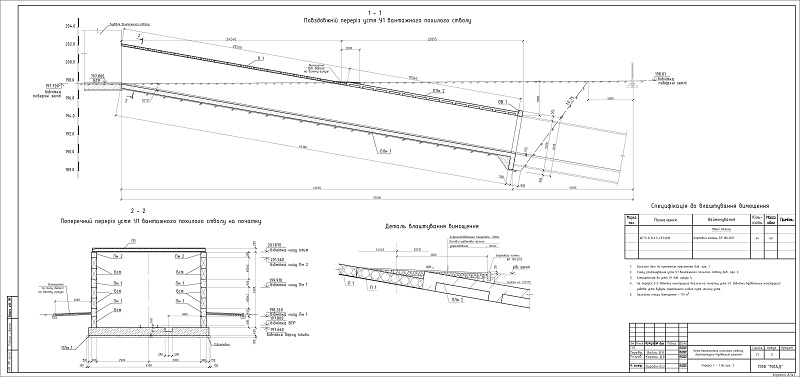

We have completed a project for the construction of a new mine (the location and organization of the customer, as well as the name of the mine, in accordance with the confidentiality agreement, we will indicate upon request and after agreement with the Customer) regarding the design of the construction of three (human, carpet and cargo) inclined shafts of the mine. The coal regions of Ukraine differ from others in their complex engineering and geological conditions, which are taken into account in the design when choosing schemes for opening and preparing for the extraction of coal reserves, structures for fixing capital and development workings, complex mechanization of mining operations and coal mining. Not every organization is able to solve at least one of these issues of complex design of a coal mine. The design of inclined shafts of this mine was complicated not only by difficult mining and geological conditions, but also by the need to conduct shafts through alluvial clays, loams and, most difficultly, sands, which, like a cherry on a cake, completed the list of difficulties and conditions of the project. Miners know the ways and methods of tunneling in the sand. But these ways and methods are very costly and not every customer can afford to spend extra money. And that is why the task was to use the existing experience and knowledge of all existing (but rather expensive) methods and methods to find a method that, on the one hand, would be affordable for the Customer, and on the other hand, would ensure safety during tunneling and reliable operation production for many years to come. After all, capital workings, and even more so shafts, serve the entire life of the mine. Our designers include experienced mine builders with practical experience in the design and construction of permanent workings in complex mining and geological conditions of construction, including such as alluvial clays, loams, sands and bedrocks (argillites / siltstones), as well as specialists who own the methods of mathematical modeling, the development of block diagrams for the implementation of the finite element method, and so on. At the stage of pre-project studies, we performed multi-variant modeling of permanent shaft support in areas with different engineering and geological conditions (sands, clays, loams, bedrocks) containing coal seams implemented by the finite element method for comparison with regulatory methods and indicators of stability and reliability. The selected types of fastening (the possibility of using which was confirmed by calculations and checked for compliance with regulatory documentation), taking into account the specifics of the tunneling technology for each of them, were calculated in terms of the cost of a full range of works on their installation.Graphic materials and calculations, as well as selected and calculated options for fixing inclined shafts in different areas (clay, loam, sand) were presented to the Customer, which gave him the opportunity to choose those solutions that best meet both the Customer's requirements and regulatory requirements for stability, reliability and service life of the designed workings. The decisions made based on the results of pre-project studies were embodied in the design documentation of the "P - project" stage, which will be further developed and detailed in the design documentation of the "P - working documentation" stage.